“Inspection of components for motor vehicles”

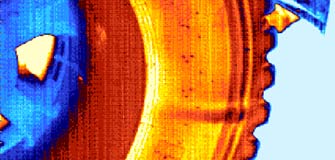

The motor industry is showing more and more interest in the use of fiber – reinforced plastic materials, also used in typically structural elements such as springs for suspensions and transmission components. Typically, non-structural elements made of composite materials are: body parts, truck cabins, spoilers, control boards, tool panels, lighting cases, bumpers. One of the strengths for the development of composite materials in cars was the possibility to obtain light materials that decrease fuel consumption. Through NDT methods, DES carries out the process control for the manufacturing and assembly of mechanical car components. We also use non-destructive thermographic control methods stimulated by laser sources on thin welded joints. This practice helps to detect defects, cracks and delaminations.