“Process control and predictive maintenance”

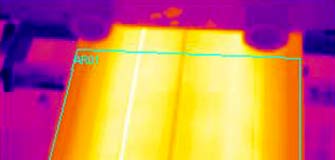

Maintenance is presently considered one of the main activities for company competitiveness. Companies cannot be competitive without an effective control over equipments costs and over the quality and time of production. Working conditions, and thereby the performance of a production unit, are directly linked to the effectiveness of maintenance tools. Predictive maintenance allows for observation and monitoring of deterioration during the lifetime of devices, by anticipating the possibility of intervention and by reducing production standstills. DES optimizes and controls the parameters of a productive process by using the thermographic method, with constant monitoring and implementation of predictive maintenance systems of components and machinery in industrial facilities.